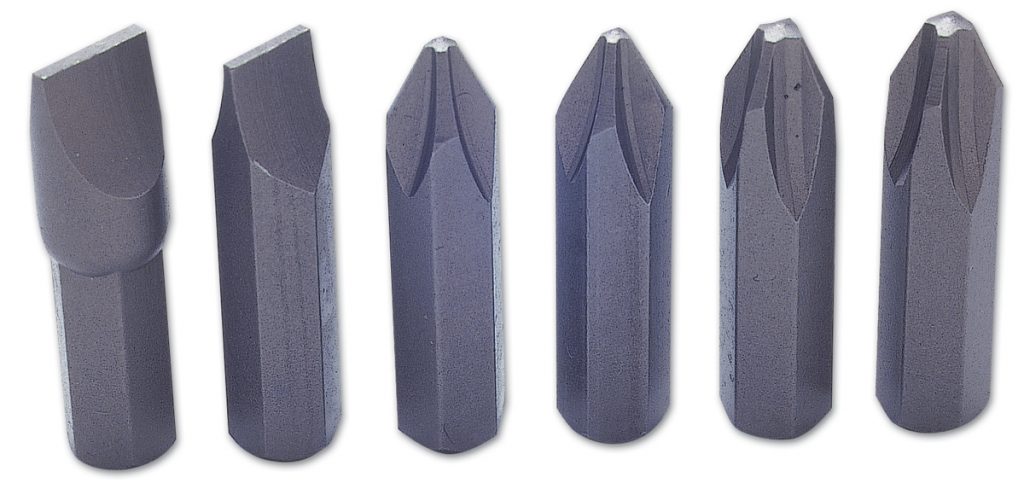

An impact driver is a device or a tool that delivers a strong, unforeseen rotational force and forward thrust when struck on the back with a hammer. The impact driver is often used by mechanics to loosen larger screws and nuts that is mordantly frozen or over-torqued. The bit set for impact driver is meant to solve problems faced by professionals and homeowners.

How does a bit set impact driver work?

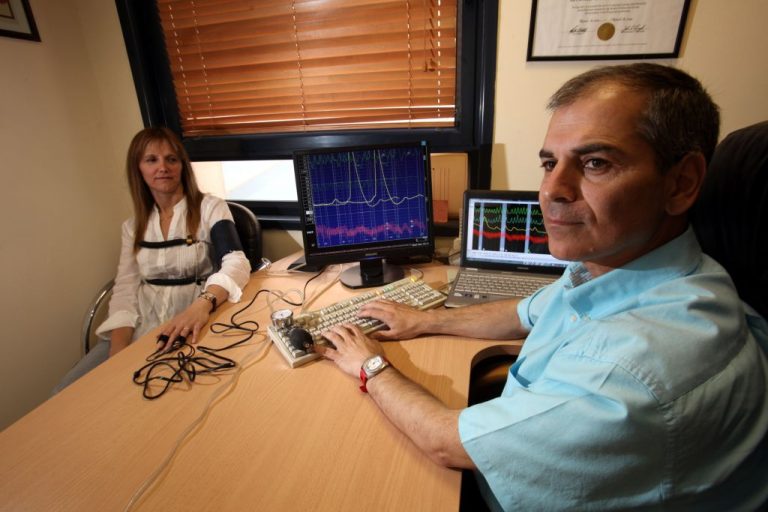

Some professionals and homeowners tend to find themselves using impact drivers instead of cordless drills, especially with the advent of bit sets with hex-shank accessories that are specifically designed to withstand the stresses that these drivers impose on a bit.

12 bit set for impact driver are high-torque tools primarily used for driving screws and tightening nuts an operation known as nut set. The chuck accepts only bits with a quarter-inch hex shank. You either pull up on the chuck sleeve to insert a bit or you just slip the bit into the chuck.

The tools are lighter, smaller and portable than drill drivers, and although 12 bit set for impact drivers are not as versatile, they will perform many of the same functions. Since the torque output is higher than a typical drill driver, it gets work done more efficiently.

How to use a bit set impact driver?

A 12 bit set Impact drill is used to apply maximum power when setting a screw or used to torque a bolt. It does so by using concussive blows along with the direction of rotation. A standard drill uses only an electric motor to turn the driver. An impact allows some rotation to occur before sending a concussive blow thus allowing the driver to apply more force than a standard drill which is similar to an impact gun for tightening lug bolts on a car.

One important factor to know is that the function of a bit set for impact driver is to provide an axial vibration to assist. This is useful primarily for rock or masonry bits. A twist bit or spade bit used in steel or wood, respectively would not benefit at all from an impact force. Twist bits and spade bits drill or cut by a shearing action or force applied to the material being drilled.

The Impact during drilling would just dull the bit. A masonry bit drills by crushing the material at the face of the bit, therefore, the impact increases the frequency of rock crushing force applied. An impact driver is specially designed for driving screws. A drill is designed for drilling holes. An impact driver is a bit like a drill with the hammer on.